Babak Ziaie

Current PhD Student

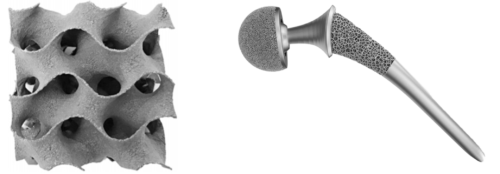

Design and development of advanced porous implants through topology optimization and additive manufacturing

Research Project Summary:

Nowadays, Biomedical devices play a vital role in human lives, so copious parameters; such as gender, age, physical and body gestures, place of implants, and even the patients’ diseases and the stage of osteoporosis should be considered when designing and manufacturing them. It is crystal clear that “customization” is one of the most important features of advanced biomedical devices. Due to limitations, fabricating patient-specific implants implementing conventional manufacturing methods will encounter an array of challenges and demands. Copious of these challenges and limitations can be mitigated or even completely solved by using AM technology. State-of-the-art AM machines provide us with immense opportunities by which we can manufacture components with desired characteristics. We can fabricate desirable surfaces and shapes with porosity, which is beneficial for osseointegration and bone ingrowth, and based on the model of implants the shape of unit cells, pores, and strut sizes can be optimized to reach the ideal stiffness.

The main aim of this project is to replace the solid metal hip joint implant made from titanium alloys (such as Ti6Al4V alloy) with a porous structure to enhance its structural performance and biocompatible characteristics. The research involves theoretical study, computational analysis, and experimental work. The research will be multidisciplinary including FEA (finite element analysis), topology optimization (TO), additive manufacturing (AM), material characterization, and mechanical testing. The morphology of the topologically optimized scaffold, such as porosity, pore size, and pore interconnectivity, will be analyzed for mechanical properties and biological properties, and then mechanical testing will be conducted to investigate the material properties of the finalized model.

Bio:

Babak Ziaie graduated in Mechanical Engineering (B.Sc.) from the University of Tabriz. In 2013, He obtained his master’s degree in Mechanical Engineering from K. N. Toosi University of Technology. Right after graduation, he started working as a Mechanical and Manufacturing engineer. He founded TPP Co. in 2014 where he worked as a shareholder, board member, and CEO. He has wide experience in designing, manufacturing, and reverse engineering high-tech components utilized in diverse industries. He was also involved in projects regarding designing and manufacturing components of dental implants, such as standard and pre-milled abutments. In 2022, he was successful in being awarded a MOCHAS Ph.D. Scholarship at the Faculty of Engineering, at the Atlantic Technological University, Ireland.

Profile Links:

LinkedIn: https://www.linkedin.com/in/babak-ziaie-552b3281/

ResearchGate: https://www.researchgate.net/profile/Babak-Ziaie

Google Scholar: https://scholar.google.com/citations?hl=en&user=czNsMUsAAAAJ

Papers

- Babak Ziaie, S. Mohammad Reza Khalili, “Evaluation of Fatigue Life for Dental Implants

Using FEM Analysis”. 2021, 3(4) : 300-313.https://doi.org/10.3390/prosthesis3040028 - Mohammad Reza Khalili, Babak Ziaie, Mahmoud Kazemi, “Finite element analysis for

dental implants subjected to thermal loads”. Journal of Dental Medicine. 2014; 26(4) : 270-280

Presentations

- Babak Ziaie, Mohamad Reza Khalili, Ali Davar, “Finite element analysis for dental implants subjected to fatigue loads”, 21st International Conference on Mechanical Engineering, 7-9 May ISME 2013, Tehran

- Babak Ziaie, Mohamad Reza Khalili, “Numerical analysis for dental implants subjected to thermal loads”, National Conference on Mechanical Engineering, 30 May 2013, Malayer