Home » Research » Research Centres/Groups/Units » Contract Research Unit (CRU) » CRU Case Studies » Merenda

Merenda

Merenda

Project Scope

Merenda continually strive to optimise their internal processes and develop new techniques and product lines. One of Merenda’s specialist products involves the application of a primer coating to one side of an ABS polymer sheet. The ABS sheet is delivered to the priming line from a continuous roll. The liquid primer is delivered to a set of two rollers. One of the rollers has a compressible surface which spreads the primer over the ABS sheet, and this operation is currently manually controlled. Merenda sought to incorporate a cost effective primer thickness measurement system to provide enhanced control and cost management of this product.

ATU Sligo carried out research for Merenda which included:

- Research and identification of appropriate film thickness measurement technologies

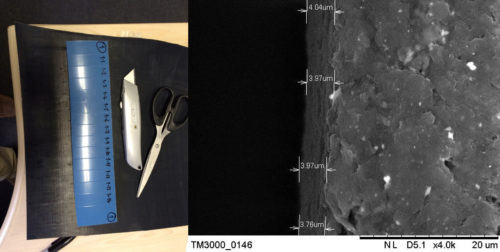

- In-house measurement of the product using manual and microscopic precision techniques to establish typical thickness ranges and variations

- Outline system specification with product samples distributed to metrology vendors

- Cost estimates for measurement system installation

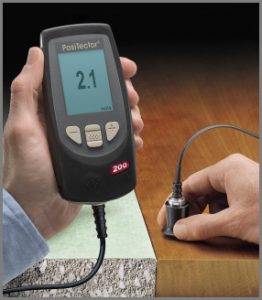

- Identification of low-cost ultrasonic measurement option for batch measurement

Company Overview

Merenda Ltd. provides wood veneer and edge banding products and services to a worldwide customer base.

Project Outcomes

The project resulted in a greater understanding of the ABS sheet product and its variables, and the type of film thickness measurement systems available including typical installation costs. This information is crucial to the company in making investment decisions in relation to the ABS product line. The identification of the hand held ultrasonic measurement tool provides a low-cost investment option which also has potential for use on other Merenda product lines.

Sample preparation and SEM imaging

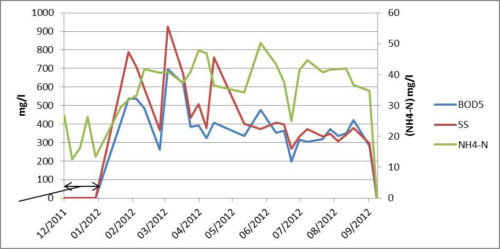

Test data analysis

Low-cost measurement option – Ultrasonic method.