Home » Research » Research Centres/Groups/Units » Contract Research Unit (CRU) » CRU Case Studies » ATA Air Tools

ATA Air Tools

ATA Air Tools

Project Scope

ATA have sought assistance form ATU Sligo to research design optimisation of the key components and performance of the motor, specifically the turbine, the power output and rotational speed.

The project work included:

- Design review

- Theoretical analysis

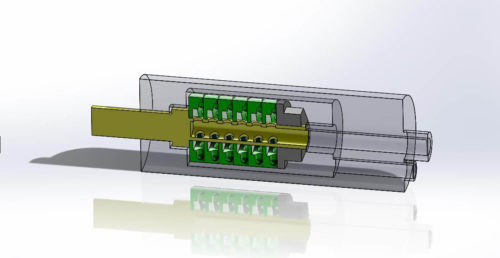

- CAD modelling

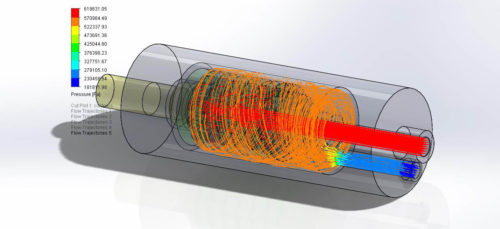

- Computational Fluid Dynamics (CFD)

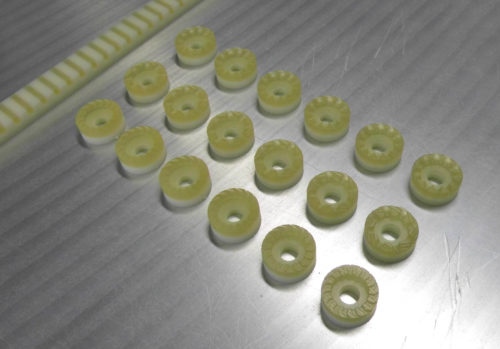

- Rapid prototyping of key components

Company Overview

ATA Air Tools (ATA) manufactures and distributes pneumatic air tools to over 50 countries in major industries such as Aerospace and Automotive. Pneumatic tools are most commonly power by compressed air through a vane motor. This type of motor requires lubrication which can be problematic for many applications in particular in the aerospace sector. ATA have developed an innovative air driven motor which removes the need for lubricant, and also achieves the required torque in a compact design.

Project Outcomes

Through the theoretical and CFD analysis the project delivered a more developed understanding of the motor performance, in particular the airflow through the turbine, optimised turbine design and options to control the natural rotational speed. The CAD modelling and rapid prototyping provided visual aids for manufacturing research and key components for performance testing. ATA now intend to build on this research in scaling the design to a range of tool products.

Client Testimonial

“The work carried out by Contract Research Unit (CRU) has proved invaluable in the design of our latest high-speed air driven turbine motor. The CFD analysis provided allowed us to experiment with various jet configurations, these were then 3D printed by Contract Research Unit (CRU) enabling us to run the necessary power, torque & speed tests.

This process allowed us to optimise the motor output while learning a great deal about the flow & expansion of the air through the assembly. I look forward to working with Contract Research Unit (CRU) on further design projects in the future.”

3D CAD model and CFD analysis

3D CAD model and CFD analysis

3D printed turbines for testing