Mandana Kariminejad

Current PhD Student

Wireless sensing for prediction and control of part quality in the injection molding

Resume:

Mandana received her bachelor’s degree in Mechanical Engineering at Shiraz University and then completed a master’s in mechanical engineering (Control & Dynamic system) at K.N Toosi University of Technology, Iran. Afterward, she has worked as a design engineer in the steel complex for a year and a half. She started her Ph.D. with IT Sligo in July 2020 under Dr. David Tormey and Dr. Marion McAfee’s supervision. She is investigating Wireless sensing for the prediction and control of part quality in injection molding. She is also a member of the I-Form advanced manufacturing center, and the industry partner of the project is AbbviE Ballytivnan. Her specific research interests are optimization and control, injection molding, additive manufacturing, mathematical modeling, simulation, and Machine learning.

Resume:

Mandana received her bachelor’s degree in Mechanical Engineering at Shiraz University and then completed a master’s in mechanical engineering (Control & Dynamic system) at K.N Toosi University of Technology, Iran. Afterward, she has worked as a design engineer in the steel complex for a year and a half. She started her Ph.D. with IT Sligo in July 2020 under Dr. David Tormey and Dr. Marion McAfee’s supervision. She is investigating Wireless sensing for the prediction and control of part quality in injection molding. She is also a member of the I-Form advanced manufacturing center, and the industry partner of the project is AbbviE Ballytivnan. Her specific research interests are optimization and control, injection molding, additive manufacturing, mathematical modeling, simulation, and Machine learning.

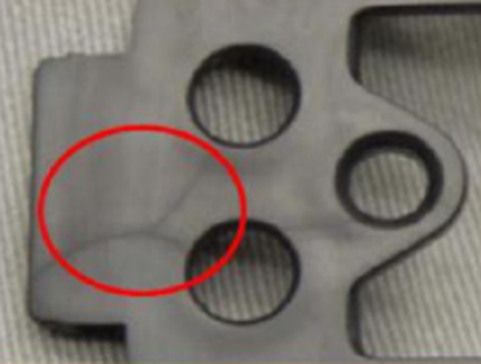

The residual stress and weld lines defects on the injection molded part.

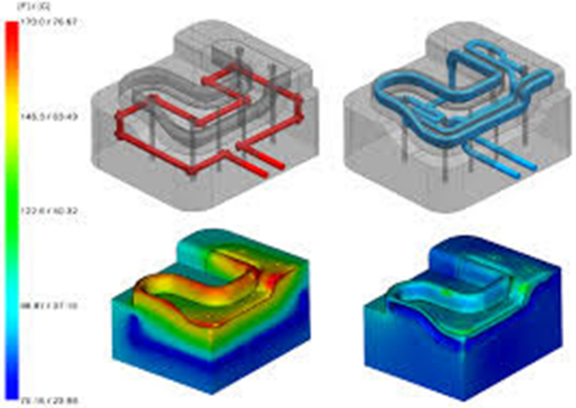

A significant goal of injection molding research relates to reducing cycle time while maintaining quality and efficiency. Replacing conventional cooling circuits with conformal cooling channels is the best approach to achieve this goal since the cooling cycle is two-thirds of the processing time. Another method for enhancing efficiency is using wireless sensing to monitor the crystallization kinetics and morphology of polymers with real-time data, optimizing the process. This data can also be employed to develop a model for process control.

The heat efficiency of conformal cooling channels vs. conventional cooling channels

Hence, Mandana is attempting to optimize the part quality and enhance the efficiency of the process while preserving the quality criteria.

The project aims can be summarized as the following:

- investigate a range of wireless in-mold sensing options for monitoring part quality

- Predict the residual stress (warpage, shrinkage) and weld lines based on this data

- Enhance the part quality by achieving the required dimensional tolerances and stability

- Exploit the model for predicting residual stress, warpage, shrinkage, etc.

- Reducing cycle time by the current cooling method and conformal cooling channels

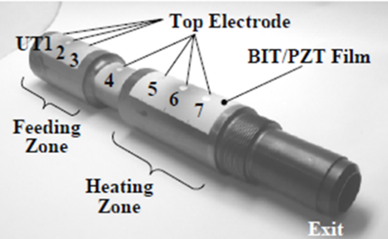

For the beginning, a suitable sensor should be selected for real-time monitoring. There are wide ranges of in-mold sensors such as ultrasonic sensors, pressure sensors, acoustic sensors, etc. The particular type of ultrasonic sensor has been selected as the in-mold sensor. This sensor will be able to monitor different properties of the polymers and tooling. She is also working on the review paper about ultrasonic sensors’ applications in the injection molding process, which will be submitted in early 2021.

The fabricated ultrasonic sensor on the barrel of the injection molding

I am just new here, but the PEM Centre and IT Sligo friendly environment motivate me to do my best about my project. Dr. David Tormey and Marion McAfee’s useful feedbacks and ideas about the project encouraged me to work with more motivation. I hope I finish my Ph.D. with the best achievement and pursue my goal to a higher degree.

Profile Links:

https://www.pemcentre.ie/ms-mandana-kariminejad-phd-research

https://www.researchgate.net/profile/Mandana-Kariminejad

https://scholar.google.com/citations?pli=1&authuser=3&user=O5loMSkAAAAJ